Researchers at the University of British Columbia have innovated a method to transform asphaltene, a byproduct of bitumen processing, into carbon fibres.

Bitumen from Alberta’s oil sands, typically restricted for use as fuel or asphalt, could now be transformed into more useful and valuable carbon nanofibres, say local experts working on the technology.

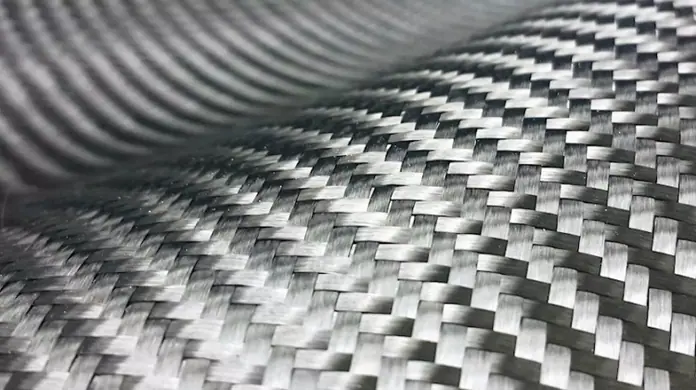

UBC materials engineer Dr. Yasmine Abdin, alongside Dr. Frank Ko from the Faculty of Applied Science and Dr. Scott Renneckar from the Faculty of Forestry, is deploying techniques such as electro-spinning and melt spinning to create sub-micron fibres approximately 500 nanometres in diameter.

Electrospinning occurs when a liquid polymer solution is subjected to a high electric field, causing it to stretch into extremely thin fibres as the solvent evaporates, which are then collected to form a fine mesh. Melt spinning—melting a polymer and extruding it through spinnerets to form continuous fibres—is a process more suitable to polymers that melt easily, which includes the water-wet oil sands of Alberta.

Abdin and co. this year launched their research into a startup, Fibernx Technologies, with an eye toward commercializing their innovation by the end of 2024.

What commercialization opportunities await the fledgling firm? Demonstrating excellent tensile properties and electrical conductivity, Fibernx’s product is poised to serve the electric vehicle market and other possible sectors, according to Abdin.

“Carbon-fibre bodies can compensate for the weight of the typical EV battery pack,” the UBC assistant professor informed The Science Times. “Using carbon fibres in the chassis helps the battery stay cool, improving safety and extending the driving range.”

The company is motivated by the Carbon Fibre Grand Challenge, a multi-phase competition with over $20 million on the line. The Alberta Innovates competition carries the objective of accelerating development of large-scale production pathways for short and continuous carbon fibre from bitumen-derived feedstocks and promoting their use in manufactured products.

Abdin’s team has already won the first two phases of the challenge. Phase three, the toughest yet, demands successful demonstration of pre-commercial production.

“In phase three, which is underway now, we want to make sure our fiber properties are reliable and consistent in large production rates,” Abdin told the Times. “After phase three is done, we are looking at full commercialization.”

In addition to establishing scale, Alberta Innovates also expects a solution that is low-cost. So far, Fibernx can produce its special fibres for $12 per kilogram, compared to a current commercial cost of more than $30—though Alberta’s challenge has set the high bar to a steely $9/kg.

The startup earned a Top 16 spot in this year’s New Ventures BC Competition.

Alberta’s oil sands, the world’s largest crude oil deposit, contain 97% of Canada’s oil reserves.