Bitumen from Alberta’s oil sands, typically restricted for use as fuel or asphalt, can now be transformed into more useful and valuable carbon nanofibres, say local experts working on the technology.

UBC materials engineer Dr. Yasmine Abdin, alongside Dr. Frank Ko from the Faculty of Applied Science and Dr. Scott Renneckar from the Faculty of Forestry, is deploying techniques such as electro-spinning and melt spinning to create sub-micron fibres approximately 500 nanometres in diameter.

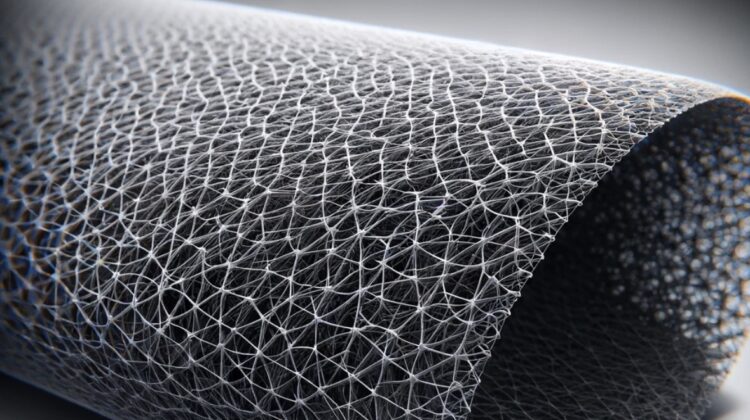

Electrospinning occurs when a liquid polymer solution is subjected to a high electric field, causing it to stretch into extremely thin fibres as the solvent evaporates, which are then collected to form a fine mesh.

Meanwhile, melt spinning—melting a polymer and extruding it through spinnerets to form continuous fibres—is a process more suitable to polymers that melt easily, which includes the water-wet oil sands of Alberta.

Abdin and co. this year launched their research into a startup, Fibernx Technologies, with an eye toward commercializing their innovation.

The company is currently motivated by the Carbon Fibre Grand Challenge, a multi-phase competition with over $20 million on the line.

The Alberta Innovates-powered competition carries the objective of accelerating development of large-scale production pathways for short and continuous carbon fibre from bitumen-derived feedstocks and promoting their use in manufactured products.

Abdin’s team has already won the first two phases of the challenge.

Phase three, the toughest yet, is underway now and demands successful demonstration of pre-commercial production while also considering cost thresholds.

In addition to front-running the Carbon Fibre Grand Challenge in Alberta, Fibernx is establishing accolades in its home province as a Top 10 finalist for this year’s New Ventures BC Competition.

Now in its 24th year, the annual competition highlighting tech innovation across B.C. culminates later this month at an in-person event at the Stanley Park Pavillion.